“Hey Mister, when are we gonna print the rest of the cat?” Aiden asked.

“Well, we could do it on Tuesday, oh…. wait, I am going to be away next week, but you all should try it Tuesday anyway. You don’t need me there for that,” I said. Aiden and his friends seemed surprised.

“Wait, we can try it without you!?”

“For real!?”

“Go for it! You built it. If it breaks, either you’ll figure it out or we’ll figure it out once I’m back."

* * *

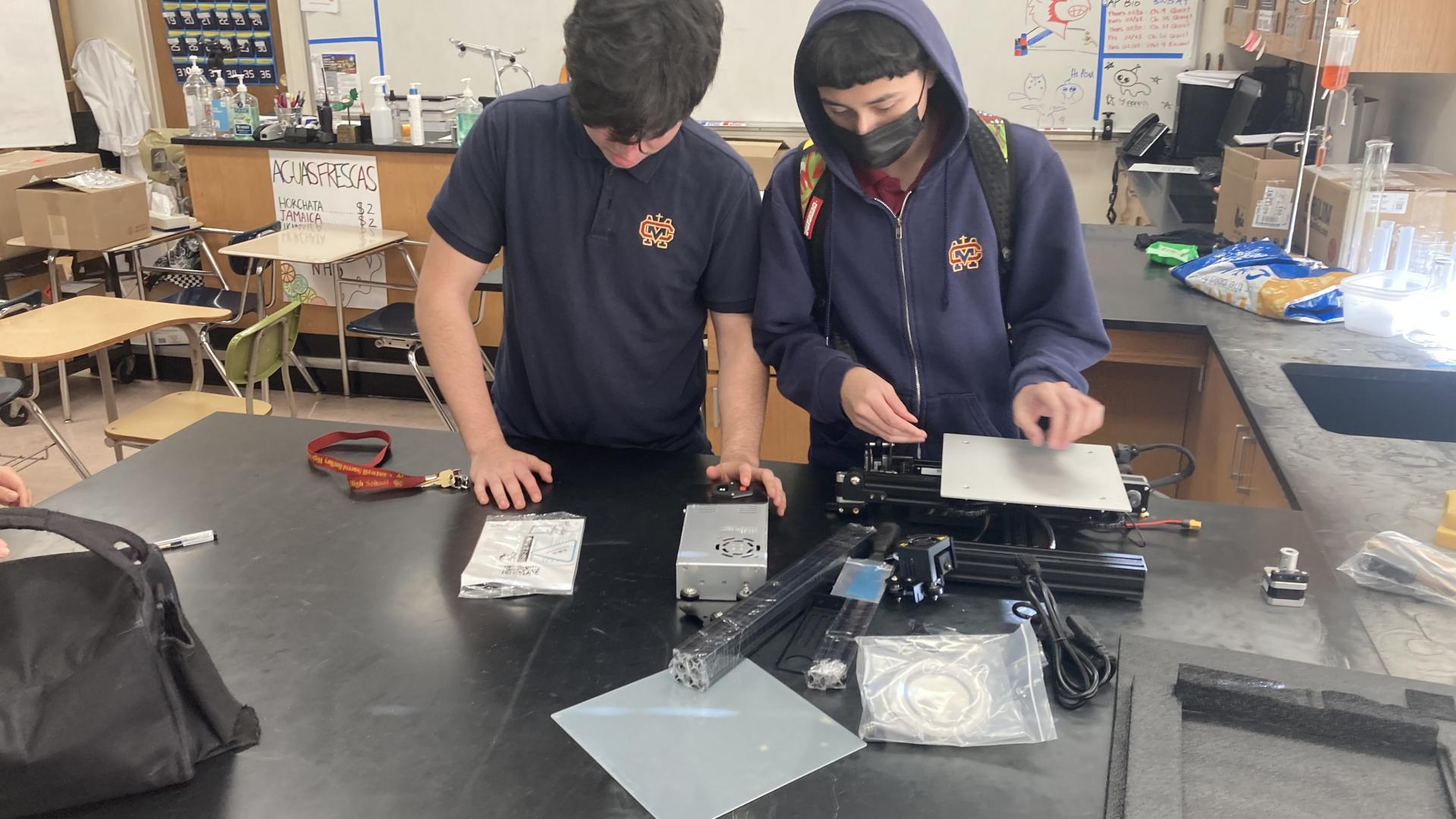

Our school recently received a grant from the College Football Playoff Foundation to buy the parts and supporting equipment for two 3D printers.

Learning how to use a 3D printer is a great educational opportunity, but as someone who grew up in a house with all sorts of projects and unconventional DIY solutions, I think making the printers themselves from a box of parts is an even more valuable practice. Before I graduated high school, I built many contraptions with my siblings and parents, including a 3D printer, a forge, trebuchets, cabinets, a garage roof, a pizza oven, and a sailboat.

Learning how to use a 3D printer is a great educational opportunity, but as someone who grew up in a house with all sorts of projects and unconventional DIY solutions, I think making the printers themselves from a box of parts is an even more valuable practice. Before I graduated high school, I built many contraptions with my siblings and parents, including a 3D printer, a forge, trebuchets, cabinets, a garage roof, a pizza oven, and a sailboat.

I remember when we first moved into our current house when I was in third grade, my dad and his brother did some demolition on the kitchen and then as a family we went to IKEA to pick out new cabinets and drawers. We loaded up the boxes of parts into the car, and during a couple evenings the next week, we sat in the living room on the carpet and put together the IKEA furniture. Even now, a couple of times a year, Dad will point to the cabinet in the corner of the kitchen and proudly say, “That’s the cabinet that Ella built!” Ella was 4 when we built the cabinets, but with help and encouragement, she was able to do her part. She is now a freshman at Notre Dame studying to be a mechanical engineer.

Those projects and the culture of taking things apart and remaking them were incredibly important to my development. I became competent in all sorts of useful skills and developed a sense of agency, especially in terms of the man-made machines I interact with every day.

I recently fixed the dryer in my community’s ACE house. Living with six other teachers is super fun, but it can be a little demoralizing when the dryer stops heating up and just spins the clothes. Our options were either air drying (which, with seven people in the winter, really isn’t a great option) or going to a laundromat. I was in charge of being home when the repairman came out to fix the dryer. Within 20 minutes, the repairman had a diagnosis. He said the issue was the igniter and that the cost for labor and parts to fix it would be $250.

He was still there a half hour later. Having tried swapping out the igniter without success, he put the old igniter back in. The new diagnosis was the timing circuit, and he left to get the part. I looked up what a dryer igniter would cost, and to my surprise, the part was only $15! This made me wary of the whole repairman business, so I took apart the timing circuit, saw that a tooth that rode on a cam had been worn down, filled in the tooth with epoxy, put it back together, and voila! The dryer heats up again!!

I was able to fix the dryer because I was not afraid of taking it apart and putting it back together again. I learned this attitude in my childhood, and I was very lucky to do so. When I work with my students, I realize that too few people have these hands-on experiences in the way I did. I want my students to have agency in the world so they can look at a problem in government, their workplace, or the education system, and see themselves as capable of solving it – even if it involves taking things apart and remaking them. The best way to teach this idea of agency is fixing a dryer, but since I don’t have a stockpile of broken dryers on hand, I went for the next best thing: building 3D printers.

The last three Mondays, the small but mighty STEM club at Cantwell-Sacred Heart of Mary High School met in the biology lab to assemble the 3D printers. By building the machines themselves, the kids learn how to use them and how to take them apart and repair them. They worked together and built the printers, and though I wanted to help, I let them stumble and recover on their own. By the end of the last meeting, the kids had started both printers on the test file, a cat, using the 4 feet of filament that came with the printer kits. Tuesday morning, we came in to see two half printed cats, and we were very excited!

I hope that Aiden and the STEM club use the printers while I am gone. Only good things could come out of their adventures. Either they successfully print some stuff, which is a win, or they break something and then fix it again, which is even better.

Alliance for Catholic Education

Alliance for Catholic Education